Welcome back to Data Under Glass

Between 2022 and 2025, African agritech experienced one of the most spectacular capital destructions in emerging market history. While funding soared to a record $776 million in 2022, a silent catastrophe was unfolding beneath the surface: founders were deploying hundreds of millions into physical infrastructure (cold storage units, warehouses, processing facilities) in environments where power outages average 6-12 hours daily and maintenance requires technicians to travel 400 kilometers for a single compressor repair.

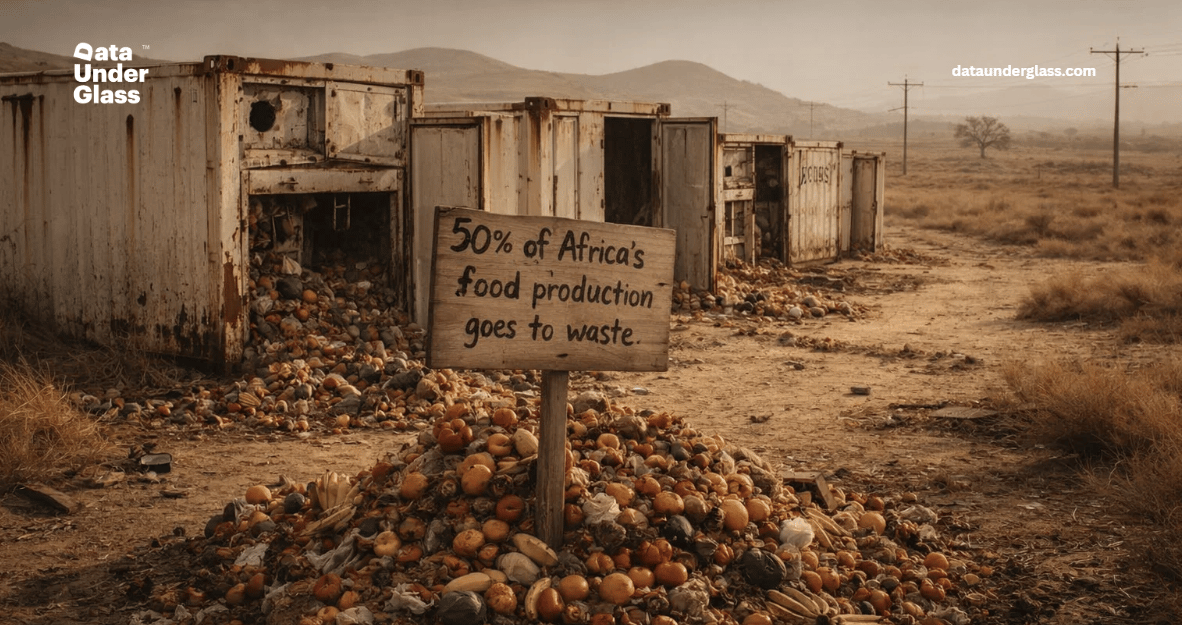

The pitch was seductive: "We're the Uber for Cold Chain." The reality? You can't Uber your way out of physics. When 50% of Africa's food production goes to waste due to lack of cold storage, the market opportunity looks infinite. But the operational hell of managing physical assets in permanent turbulence proved fatal.

This week, we deconstruct why the "asset-light marketplace" dream became a $340M lesson in the cost of ignoring infrastructure economics.

—Anderson Oz'.

From The Operator's Desk

Case In Point: In mid-2023, a West African agritech scale-up raised a large Series B to deploy 230 cold storage units across four countries. The deck was pristine: $12/day revenue per unit against $4/day operating costs. At 23% gross margins, the “Uber-for-Cold-Chain” narrative looked inevitable. Investors saw predictable cash flows and a first-mover advantage in a $936B food waste problem.

What We Caught:

Forensic diligence surfaced three structural flaws hiding beneath the spreadsheet:

Invisible Cost Of Goods Sold (COGS): Power outages in Nigeria average 12 hours daily. Diesel backup generators added an immediate $8/day to costs, double the modeled OpEx.

The Maintenance Trap: Remote deployments turned minor failures into logistics events. Compressor repairs required 400 km of travel. With parts theft and no local expertise, maintenance hit $6/day.

Unit Economics Collapse: Instead of $8/day profit, actual economics were -$6/day burn, every single unit.

The Reality:

Of the $340M raised sector-wide, $89M went into this negative-margin infrastructure. Within 18 months, the company pivoted to an “asset-light aggregator model.”

Translation: 180 units, worth $21M, were abandoned to rust.

The Intervention:

The advice was to immediately halt operations. At -$6/day per unit, the remaining runway was 14 months. The pivot wasn’t a strategy; it was containment.

The Lesson:

Digital platforms in emerging markets are only as valuable as the infrastructure beneath them. If you can’t keep the machines running when the power is gone half the day, you’re not building tech. You're subsidizing a disaster.

The Market Split: Silicon Valley Infrastructure vs. African Reality

In developed markets, infrastructure is a utility; power doesn't swing. Maintenance techs arrive in hours, not days. You can treat cold storage like cloud servers—predictable, scalable, remotely managed.

In Africa, infrastructure is an active predatory variable. Countries in sub-Saharan Africa experience annual outages from 50 to 4,600 hours, which is more than half the year for some markets. When South Africa experienced rolling blackouts for 289 days in 2023, it wasn't an anomaly; it was normal.

The fundamental error in agritech capital architecture is treating physical infrastructure like software—scalable, outsourced, and predictable. In permanently turbulent markets, infrastructure isn't a line item. It's your entire moat or your entire liability.

The structural mismatch is this: VCs funded First World business models in Third World infrastructure environments. The mathematics never worked.

The Evidence Stack

$776M: Record African agritech funding in 2022, before the infrastructure reality hit

50%: Percentage of food produced in Africa that goes to waste due to inadequate cold chain infrastructure.

6-12 hours: Average daily power outages in markets like Nigeria, forcing high reliance on diesel generators.

3x higher: Cost of electricity when using backup diesel generators versus reliable grid power.

67%: Our analysis shows this is the infrastructure failure rate, with cold chain units going offline within 18 months when maintenance and power aren't controlled.

-$6/day: The actual unit economics after power, maintenance, and theft versus the $8/day profit modeled in pitch decks.

Cold chain infrastructure in Africa doesn't fail because of mismanagement. The assumptions around the models themselves were invalid.

Flagship Insight: Power Is The Business Model

Most founders budget power at grid rates. In a country in Africa, the grid delivers about 5 gigawatts for 230 million people, the same capacity that serves Croatia's 4 million citizens; this is financial fiction.

The forensic reality: when you deploy cold storage in off-grid or unreliable-grid environments, diesel backup isn't a contingency but your primary power source. And diesel-powered electricity costs 3x more than grid power.

Consider the logistics company's model: they forecasted $4/day operating costs. But 6-hour daily outages meant diesel generators ran continuously. At 3x grid rates, power alone consumed $8/day, double the entire modeled OpEx and erasing all gross margin before a single other expense.

Then add maintenance. In remote deployments with no local parts suppliers and technicians 400 km away, a compressor failure isn't a same-day fix. It's a multi-day, multi-thousand-dollar expedition. Factor in parts theft, and your "asset" becomes a liability generating negative cash flow.

Cold storage wasn’t collateral; it was stranded capital.

You may also enjoy reading: The Venture Debt Trap: Why 73% of African Scale-Ups Defaulted in 24 Months

What's Actually Working: The 2026 Operator Playbook

If you're an investor or executive navigating agritech in 2026, your operating system must fundamentally shift from platform aggregation to infrastructure resilience:

1. Audit for Physics, Not Finance. Before examining MRR, check the mean time between failure of hardware and localized diesel costs. If the founder can't quote compressor repair costs in Tier-3 cities, margins are fiction. Ask, "What's your plan when the power's out 8 hours today?"

2. Avoid the Aggregator Trap. Two agritech startups (Gro Intelligence and iProcure) shut down in 2024. "Asset-light" pivots after raising infrastructure deployment aren't strategic repositioning—they're admissions of operational failure.

3. Verticalize the Utility Layer. 2026 winners integrate power generation, like solar, biomass, and hybrid systems, directly into infrastructure. When you own the power source, you control unit economics.

Steal This: The Infrastructure Viability Audit

Before deploying capital into physical agritech infrastructure, run these tests:

1. Power Dependency Test: Can infrastructure operate profitably if grid power is unavailable 50% of operating hours? What's your all-in cost per kWh, including backup generation?

2. Maintenance Accessibility Audit: What's the average distance to the nearest qualified technician? Can critical repairs be completed within 24 hours?

3. True Unit Economics Calculation: Recalculate using actual power costs (3x grid rates for diesel), realistic maintenance frequency, and security costs. Still profitable?

4. Abandonment Cost Scenario: If you walk away from 50% of deployed assets tomorrow, what's your write-off exposure? Is this existential?

If you fail more than two tests, your "infrastructure play" is capital destruction waiting to happen.

Field Intelligence

Signal:

Infrastructure investors demanding operator ownership, not platform aggregation

Winners verticalizing power generation into cold chain units

Asset abandonment write-offs averaged $1.2M per 10-unit cluster

Agritech funding dropped 62% YoY as infrastructure failures became visible

Noise:

"Asset-light marketplace" pivots presented as strategic evolution

Treating power as a predictable line item rather than an active predatory variable

Modeling maintenance on developed-market assumptions

The Bottom Line

The cold chain mirage wasn't a technology failure. It was an infrastructure economics failure dressed in tech-company valuations. VCs funded digital platforms that required physical infrastructure to work, then discovered that infrastructure in permanent turbulence environments doesn't behave like cloud servers.

The hard truth: In markets where power is out half the day and technicians are 400 km away, your "scalable infrastructure play" is neither scalable nor infrastructure.

It's an expensive way to learn that physics doesn't care about your pitch deck.

Today’s Recommendation

Most newsletters tell you what's trending. DUG Weekly tells you what happened, why it did, and what it means for your next decision. Every week, we deliver forensic analysis of why companies actually scale or collapse. Not news. Not motivation. Not theory.

Forward this to a founder being pitched "asset-light infrastructure plays" or a GP about to fund cold storage units in markets where power's out 12 hours daily.

Till next time, this insight is DUG Weekly!